Frame repair safety standards are paramount for Electric Vehicles (EVs) and Hybrid Vehicles due to their advanced construction featuring lightweight materials, high-voltage systems, and intricate battery packs. Certified technicians must use specialized tools and adhere to strict industry standards to minimize electrical hazards, fluid leaks, and part misalignment. The goal is to maintain structural integrity, preserve efficiency, and ensure safety during repairs, including services like car scratch repair or paint jobs. As the EV market grows, best practices emphasize minimal disruption to electrical systems and maximum structural integrity, with future trends predicting increased technological integration and sustainable repair methods.

In the rapidly evolving automotive landscape, electric vehicles (EVs) and hybrid cars are gaining popularity. As these vehicles become more prevalent on the road, understanding frame repair safety standards is crucial for maintaining their structural integrity. This article delves into the essential frame repair safety standards required for EVs and hybrids, highlighting key considerations and best practices to ensure safe repairs. We explore future trends, emphasizing the importance of staying updated in this dynamic industry.

- Understanding Frame Repair Safety Standards for Electric and Hybrid Vehicles

- Key Considerations for Ensuring Safe Frame Repairs

- Best Practices and Future Trends in EV/Hybrid Frame Repair Safety

Understanding Frame Repair Safety Standards for Electric and Hybrid Vehicles

Frame repair safety standards are paramount when handling Electric Vehicles (EVs) and Hybrid Vehicles, given their unique construction and sensitive components. Unlike conventional cars, EVs and hybrids often feature lightweight materials, high-voltage systems, and intricate battery packs integrated into the vehicle’s frame. Thus, any frame repair or structural work necessitates a deep understanding of these advanced systems to prevent damage or disruption.

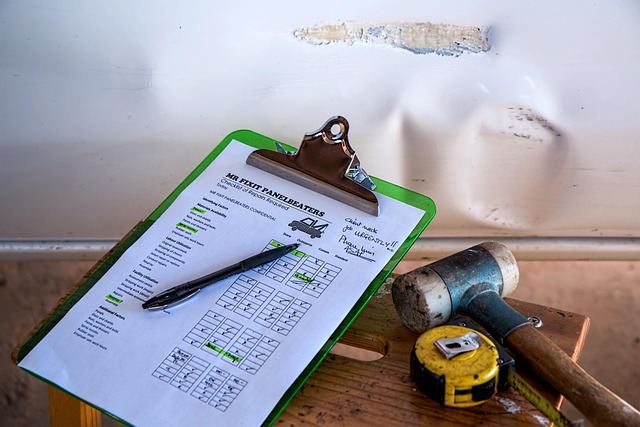

When visiting a car bodywork or Mercedes Benz repair shop for frame repairs, ensure they adhere to strict industry standards. Certified technicians should employ specialized tools and techniques tailored to EV/hybrid frames, minimizing the risk of electrical hazards, fluid leaks, and part misalignment. The goal is to preserve the vehicle’s structural integrity, efficiency, and overall safety—a vital consideration in ensuring smooth operations for these cutting-edge vehicles on the road.

Key Considerations for Ensuring Safe Frame Repairs

When it comes to frame repair for Electric Vehicles (EVs) and Hybrid Vehicles, safety should always be the top priority. These vehicles, while cutting-edge in technology, often have unique structural considerations compared to traditional internal combustion engine cars. Key considerations include understanding the specific materials and design elements used in these vehicles’ frames, as well as adhering to specialized frame repair safety standards.

Specialized training is essential for technicians tasked with repairing EVs and hybrids, as these vehicles may incorporate advanced materials like lightweight composites or have complex electrical systems integrated into their frames. Proper use of protective gear, adherence to ventilation guidelines, and understanding the potential hazards associated with battery packs are all integral parts of the process. Moreover, ensuring that any replacement parts used in car collision repair meet the required safety standards for EV and hybrid vehicles is paramount to maintain structural integrity and overall vehicle safety during repairs, alongside considerations for services like car scratch repair or car paint services.

Best Practices and Future Trends in EV/Hybrid Frame Repair Safety

As the electric vehicle (EV) and hybrid market continues to grow, so does the need for specialized and safe frame repair techniques. Best practices in EV/hybrid frame repair focus on minimizing disruption to the vehicle’s electrical systems and maximizing structural integrity. This includes using certified parts and tools, as well as adhering to stringent frame repair safety standards. Trained technicians must employ precise measurements and advanced tools to ensure alignment and structural accuracy without compromising the vehicle’s battery pack or other sensitive components.

Future trends in EV/hybrid frame repair are expected to emphasize further integration of technology and sustainability. Automated systems for measuring and repairing frames could become more prevalent, enhancing efficiency and reducing human error. Additionally, as these vehicles continue to evolve, so will the need for collision repair centers to invest in specialized training and equipment tailored to auto body work on EVs and hybrids. Auto detailing services for these vehicles may also see advancements in eco-friendly materials and techniques to meet growing consumer demands for clean, safe, and sustainable repairs.

In conclusion, adhering to stringent frame repair safety standards is paramount for ensuring the integrity and performance of electric and hybrid vehicles. By understanding the unique considerations and best practices outlined in this article, repair facilities can effectively navigate the challenges posed by these advanced automotive technologies. As the EV and hybrid market continues to grow, maintaining robust safety protocols will be essential to fostering consumer confidence and ensuring the long-term reliability of these vehicles.