Frame repair safety standards vary significantly across vehicle manufacturers due to differing structural complexities and design philosophies. Collision repair services play a critical role in upholding these standards through specialized equipment, adherence to manufacturer guidelines, and techniques like paintless dent repair. Skilled professionals ensure vehicles are restored to pre-collision conditions, enhancing safety, reliability, performance, and longevity on the road. Consumers should look for reputable shops that prioritize safety, transparency, and industry certifications to ensure high-quality frame repairs that meet OEM guidelines.

Frame repair safety standards are not one-size-fits-all in the automotive industry. Each vehicle manufacturer has its own set of guidelines, tailored to their specific designs and materials. This can pose challenges for technicians and consumers alike, as understanding these variations is crucial for ensuring safe and effective repairs. In this comprehensive guide, we’ll explore frame repair safety standards, delve into the differences between manufacturers, and provide essential tips for professionals and car owners.

- Understanding Frame Repair Safety Standards: A Comprehensive Overview

- Variations Across Vehicle Manufacturers: Case Studies and Best Practices

- Ensuring Safe and Effective Frame Repairs: Tips for Technicians and Consumers

Understanding Frame Repair Safety Standards: A Comprehensive Overview

Understanding Frame Repair Safety Standards: A Comprehensive Overview

In the realm of automotive restoration, especially when addressing frame repair safety standards, each vehicle manufacturer has its own set of guidelines and protocols. This diversity stems from the unique structural complexities and design philosophies that differ across makes and models. For instance, a high-performance sports car may have a more intricate frame setup compared to a family sedan, necessitating distinct safety measures during repair or restoration. These standards encompass various aspects, including the use of specialized equipment, adherence to specific techniques, and compliance with environmental regulations, all aimed at ensuring the structural integrity and safety of the vehicle post-repair.

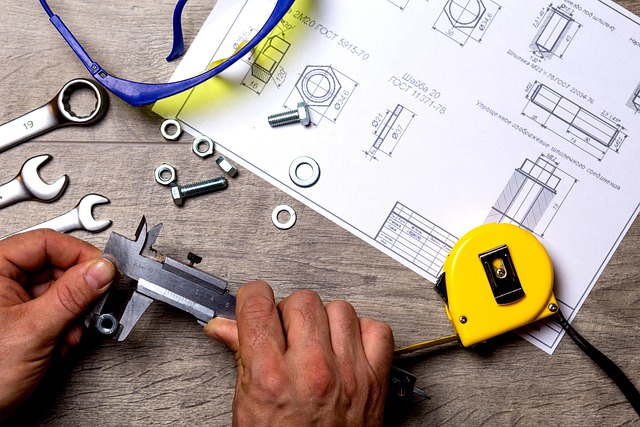

Collision repair services, in particular, play a pivotal role in maintaining these safety standards. Professionals skilled in frame straightening, alignment, and various dent removal techniques—such as paintless dent repair—are crucial in restoring vehicles to their pre-collision condition. By following manufacturer guidelines and leveraging advanced tools and technologies, these experts can accurately rebuild frames, ensuring the vehicle’s safety and reliability on the road. This comprehensive approach not only preserves the vehicle’s structural soundness but also enhances its overall performance and longevity.

Variations Across Vehicle Manufacturers: Case Studies and Best Practices

Frame repair safety standards vary significantly across vehicle manufacturers, reflecting the diverse approaches and complexities inherent in different car models. Each automaker has its own set of guidelines and protocols for frame repair, often tailored to specific vehicle architectures and safety features. These variations can be attributed to advancements in automotive design, materials used, and crashworthiness requirements. For instance, modern cars with advanced steel alloys and complex structural layouts necessitate specialized repair techniques that older models might not require.

Case studies from leading auto manufacturers highlight best practices in frame repair safety standards. Toyota, for example, emphasizes precision alignment and the use of original equipment parts to ensure structural integrity during auto collision repair. Conversely, Ford focuses on robust quality control measures and trained technicians to handle complex frame repairs, particularly in its pickup truck lineups. These examples underscore the importance of adhering to manufacturer-specific guidelines in an automotive body shop, ensuring that car repair services are not just effective but also safe and reliable for drivers.

Ensuring Safe and Effective Frame Repairs: Tips for Technicians and Consumers

Ensuring safe and effective frame repairs is paramount for both technicians and consumers alike. Given that frame repair safety standards vary by vehicle manufacturer, it’s crucial to stay informed about the specific protocols for your car make and model. Technicians should always refer to the original equipment manufacturer (OEM) guidelines, which provide detailed instructions tailored to each vehicle’s unique design and structural integrity requirements.

For consumers considering frame repairs, transparency is key. Ask your mechanic about their adherence to industry standards and certifications. Reputable shops will prioritize safety by utilizing proper tools, materials, and techniques. Moreover, they’ll employ advanced equipment for measurements and alignment, ensuring that your car’s structure is restored to its pre-accident condition. Remember, a quality frame repair not only enhances safety but also preserves the overall value and performance of your vehicle, including any future auto detailing or bumper repairs.

Frame repair safety standards, while vital to vehicle structural integrity, vary significantly between manufacturers. This inconsistency presents both challenges and opportunities for technicians and consumers alike. Understanding these variations and adhering to best practices ensures safe, effective repairs. By staying informed about specific manufacturer guidelines and implementing sound techniques, professionals can maintain high-quality work, while consumers can rest assured their vehicles are in capable hands. Ultimately, prioritizing frame repair safety standards is key to fostering trust and enhancing roadworthiness.