Recent revisions to frame repair safety standards highlight the increasing use of high-strength steel in vehicle construction, necessitating a shift in auto body shop practices. Shops must prioritize precision alignment and structural integrity during glass repair involving these advanced materials. New protocols emphasize specialized training, detailed cutting and welding procedures, and advanced equipment to ensure worker safety and prevent failures. Compliance with updated standards is crucial for maintaining secure workspaces and enhancing the quality of post-repair vehicles.

The latest updates to frame repair safety standards, focusing on high-strength steel, mark a significant evolution in automotive restoration practices. These revisions, driven by advancements in material science, aim to enhance vehicle structural integrity and passenger safety. This article delves into the rationale behind these changes, explores critical protocol shifts for high-strength steel frame repairs, and offers practical guidance for workshop owners and mechanics to ensure compliance with the newest standards.

- Understanding the Update: Why and When Were the Standards Revised?

- Key Changes in High-Strength Steel Frame Repair Safety Protocols

- Implementing Newer Standards: Tips for Workshop Owners and Mechanics

Understanding the Update: Why and When Were the Standards Revised?

The frame repair safety standards have recently undergone significant revisions, primarily focusing on high-strength steel. This update is a direct response to the evolving automotive industry and the increasing use of advanced materials in vehicle construction. The need for enhanced safety measures became evident as cars started incorporating stronger steels and lightweight materials to improve crashworthiness and fuel efficiency.

The revision was necessary to address new challenges in auto glass repair, especially during complex automotive collision repair processes involving high-strength steel frames. Car body shops now face the task of ensuring precise alignment and structural integrity when repairing these modern vehicles, requiring a reevaluation of standard practices.

Key Changes in High-Strength Steel Frame Repair Safety Protocols

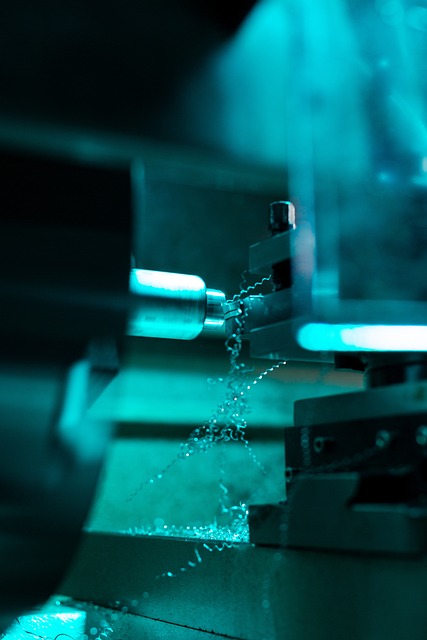

The latest updates to frame repair safety standards have brought significant changes when it comes to high-strength steel frames. One of the key modifications is the introduction of more stringent guidelines for handling and manipulation of these robust materials, reflecting their increased use in modern vehicle construction. Auto collision centers and tire services now need to adapt their practices to ensure worker safety without compromising structural integrity.

These new protocols emphasize precision and specialized training for repair technicians. The updated standards detail specific procedures for measuring, cutting, and welding high-strength steel frames, taking into account the unique properties that make them more susceptible to damage if not handled correctly. This includes recommendations for advanced equipment and tools designed to minimize stress concentrations and prevent unexpected failures, ultimately enhancing the safety of both auto bodywork professionals and the vehicles they service.

Implementing Newer Standards: Tips for Workshop Owners and Mechanics

With recent updates to frame repair safety standards focusing on high-strength steel, workshop owners and mechanics need to stay informed and adapt their practices accordingly. These new guidelines are designed to enhance worker safety during bumper repair and dent removal processes, which have become increasingly complex due to modern car designs. Understanding these changes is crucial for maintaining a compliant and secure workspace.

Workshops should invest in proper training programs that educate staff on the latest frame repair techniques and safety protocols. This includes learning how to handle high-strength steel materials effectively during car collision repair, ensuring minimal distortion and preserving structural integrity. Upgrading tools and equipment to meet new standards is also essential. By embracing these updates, workshop owners can create a safer environment for their mechanics, ultimately contributing to the quality and reliability of post-repair vehicles.

The recent updates to frame repair safety standards, focusing on high-strength steel, mark a significant step forward in ensuring the well-being of mechanics and workshop owners. By incorporating advanced materials like high-strength steel into vehicle frames, it’s crucial that repair protocols keep pace with these innovations. Understanding and implementing the revised guidelines outlined in this article will help professionals stay ahead in their field, enhancing workplace safety and the quality of repairs. These standards serve as a cornerstone for maintaining the integrity of modern vehicles, fostering a safer environment for all involved.